...

Why does tempering have to be done at all? To answer this question, we first have to explain the difference between couverture and chocolate, because as many people do not know, there is a considerable difference. Chocolate is easy to get in the supermarket, but couverture is a little more difficult. Why is that? Couverture is high-quality chocolate with a lower sugar content than conventional chocolate and with a much higher cocoa and cocoa butter content. The last two ingredients are also what make couverture so special and are the reason why it is more expensive than regular chocolate and also harder to find. In addition, the cocoa butter is the reason why couverture has to be tempered in the first place, because if this is not done, the couverture may stick in the mould or turn grey. We will now explain to you exactly what you need to bear in mind!

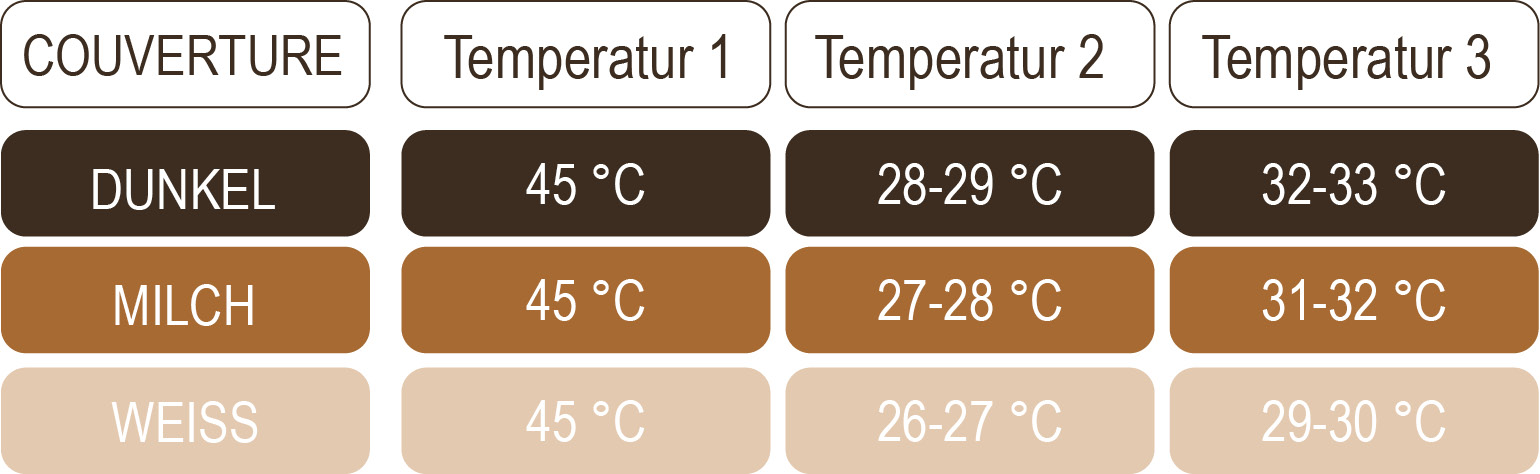

During tempering, each couverture goes through three stages. Melting, cooling and heating again. After the last stage, the couverture has reached the optimum processing temperature. The temperatures vary depending on the couverture. If you follow the table above, nothing can go wrong. To make sure that your couverture is really at the right temperature, you can also use a chocolate thermometer. The simplest method of tempering couverture is the inoculation method. In this method, 2/3 of the couverture is melted and then inoculated with 1/3 of the couverture drops. To make the whole thing a little easier to understand, let's go through it step by step with an example!

For our example we take 900 g milk couverture.

1. Put two thirds of the desired amount of couverture into the tempering unit and set it to 45 °C. So, according to our example, 600 g (2/3). Meltthe couverture with the lid closed for at least 4 to 6 hours.

2. As soon as the couverture has completely melted and reached 45 °C, add the last third of the couverture. In our example, this would be 300 g (1/3).

3. Stir the couverturedrops into the melted couverture and reset the tempering unit to 30 °C. Let the tempering unit rest, covered, for about 5 minutes. After this time, stir the couverture well and let it rest covered for another 5 to 10 minutes.

4. Now only a few small pieces of couverture should be visible. The couverture is thick and should have a temperature between 26 °C and 29 °C, which varies depending on the type of couverture. The couverture as in picture 5 above is still too thick and must be reheated.

5.a The rather thick couverture must now be heated additionally with the help of a hot air dryer until the optimal final temperature has been reached. This varies between 30 °C and 33 °C depending on the type of couverture. It is better to reheat carefully and in smaller stages than too much, otherwise the tempering process will have to be started again.

5.b If you do not have a hot air dryer, you can also heat the thick couverture over a water bath. To do this, put a little water in a pan and bring to the boil, then turn down to the lowest setting and heat the couverture in a suitable bowl over the steam. Warm the couverture carefully and not too hot.

6. Always pay attention to the pattern as shown above. The couverture is optimally tempered when you can make a pattern with a rubber scraper or spatula that remains visible on the surface of the couverture and does not disappear completely or appear very thick, as is the case in picture 5.

7. Test the result with a sample. Dip a spatula into the couverture and allow the sample to set at room temperature (max. 24 °C) for 10 minutes. If the room temperature is too high, put the sample in the refrigerator for a short time.

8. If the couverture sets quickly and has a nice sheen, you can continue to process it. If the couverture has not set optimally or not at all, you will find out in the following text what the causes may be and how you can counteract this.

The temperature of the couverture was too warm. This destroyed not all, but many stable fat crystal forms in the cocoa butter. The stable fat crystals mix with the unstable ones and many grey and white dots appear.

Add another handful of extra crushed couverture pieces to the too warm couverture and stir in carefully so that they can dissolve well and the stable fat crystals are evenly distributed.

The couverture has enough stable fat crystals, but they were processed too cold, turning the sample grey.

Reheat the couverture over a water bath or with a hot air dryer until the optimum final temperature has been reached.

If not enough stirring was done during the tempering process, it is possible that, for example, there is still warm couverture in the corner sections of the bowl that was not mixed with the cold couverture. When cooling, this becomes obvious when streaks appear. Very often this also happens towards the end of processing or when the chocolate has been reheated too much.

If this happens, the couverture can be tempered again or mixed very well at a suitable temperature. This has no effect on the quality of the chocolate. You can use the couverture for your next creation without any problems.

The above fats are what make cocoa butter and thus couverture so special. They are the reason why the products made from couverture have that beautiful sheen. The fats have different melting points of 20 °C to 47 °C and have the property of solidifying in unstable and stable crystal forms when cooling. It is precisely these fat crystals that need to be balanced in order to obtain the perfect end product, and this balancing of the fat crystals can only be achieved by tempering.

To put it more simply: tempering means processing the fat components of the cocoa butter contained in the couverture in such a way that it is easier to shape and obtains the desired gloss and break after processing (whether into bars, pralines or hollow figures).

If you do not do this, or if you make a mistake, the couverture can stick to the praline, tablet or figure moulds or (as already shown in the pictures above) take on a greyish appearance. Although this is not as visually appealing, it has no effect whatsoever on the taste and thus on the enjoyment of the sweet creation. So if the couverture did not contain cocoa butter, there would be no need to temper couverture and it would be a lot easier.

Cake icing is a chocolate-like mass that does not need to be tempered. In cake icing, the complex cocoa butter has been replaced by other fats (mostly coconut or palm fat). As a result, the cake glaze always has a nice sheen, but does not come close to the taste of the noble couverture. Accordingly, cake glaze is mainly used to coat cakes, pastries and confectionery, but never for high-quality confectionery products such as pralines or chocolate bars.

When storing couverture / chocolate, a number of things must be taken into account to ensure that it retains its quality for as long as possible.

Chocolate and couverture are very sensitive to heat. The ideal storage temperature for chocolate is18 °C. Moreover, this temperature should remain as constant as possible.

As the couverture/chocolate is sensitive to moisture, it should always be stored in dry places.

Chocolate and couverture absorb foreign odours very quickly, so they should never be stored near strong-smelling food. White chocolate in particular takes on foreign odours very quickly. To avoid this, the chocolate should be stored as airtight as possible. Make sure that the packaging is odourless.

Couverture/chocolate also does not tolerate light well and should be stored protected from it. If chocolate comes into contact with air and light, oxidation occurs. The fat contained in the chocolate dissolves and the consequences are changes in taste and an unpleasant smell. The cocoa components of chocolate contain natural substances that delay the oxidation process. Chocolate with a higher cocoa mass content is therefore better protected than milk chocolate. White chocolate contains no cocoa mass components and therefore has no protection at all, so it is particularly susceptible. To avoid oxidation, the chocolate must be stored in a dark and airtight place.

For all those who prefer to enjoy their chocolate from the fridge: To each his own taste, but this preference has more to do with a reduced perception of sweetness due to the cold (perfect for cheap, highly sugary chocolate) than with good chocolate storage. An opened chocolate is exposed to strong temperature fluctuations, a lot of humidity and strong smells from the rest of the fridge contents in the fridge. Therefore, there is actually no worse place to store chocolate. If you still prefer to enjoy your chocolate cold in the future, it is better to put it in just before eating it and avoid storing it in the fridge for a long time.

Chocolate or couverture not quite used up yet? No problem! Pour the still liquid tempered couverture onto baking paper and spread it out as evenly as possible with an angled spatula. Then place the baking paper in the fridge for about 10 minutes, or on the balcony in winter, until the chocolate has cooled down.

If the chocolate or couverture has then become nice and firm and shiny, it can be broken into small pieces and melted again for the next production or even used to inoculate the already liquid chocolate.

If the chocolate or couverture has become unevenly firm after cooling and has grey areas, this is not a bad thing at all. Break or cut the greyish chocolate into pieces and pack it in an airtight container until it melts again. This greyish chocolate should not be used for inoculation, but can be melted in the tempering unit or over a water bath and inoculated with new couverture pieces.

The chocolate/couverture can also be left in the tempering unit, but as a block it takes much longer to melt.

If you are not yet confident in tempering couverture on your own, despite the article, or if you simply want to expand your knowledge of the complex cocoa butter contained in couverture, then why not take part in our couverture tempering course? In addition to the inoculation method, you will learn another very useful tempering method and you will be guided step by step by our professional chocolatiers. We look forward to your registration!

Casting your own chocolate Easter bunnies

Casting your own chocolate Easter bunnies

Make your own decor roulade

Make your own decor roulade

Cinnamon star recipe

Cinnamon star recipe

Making Halloween chocolates

Making Halloween chocolates

Cake Recipes Convert

Cake Recipes Convert

Leave a comment